DTF printing has long ceased to be perceived as an experimental method of thermal transfer. Today, it is a full-fledged technological system in which each stage affects the next. There are no minor details here: temperature, pressure, PET film properties, adhesive powder fraction size, and even air humidity work together. That is why a sustainable result is achieved not at the expense of equipment, but by understanding the entire process of direct to film printing.

DTF printing is based on transferring images from film to fabric through thermal exposure, but the simplicity of the formulation is deceptive. It hides a chain of solutions where an error in one parameter affects the adhesion, durability and visual purity of the print.

Technological Logic Of The DTF Process

The process begins long before the heat press is turned on. File preparation plays a fundamental role. Bitmap images require a resolution of at least 300 DPI, otherwise details will be lost and visual noise will appear. Vector elements are used where edge clarity, scalability, and precise typography are important.

Working with color requires translating the design from RGB to CMYK. Without a correct ICC profile, the color result becomes unpredictable. The white underbase forms the image density, especially on dark fabrics, and directly affects the color saturation.

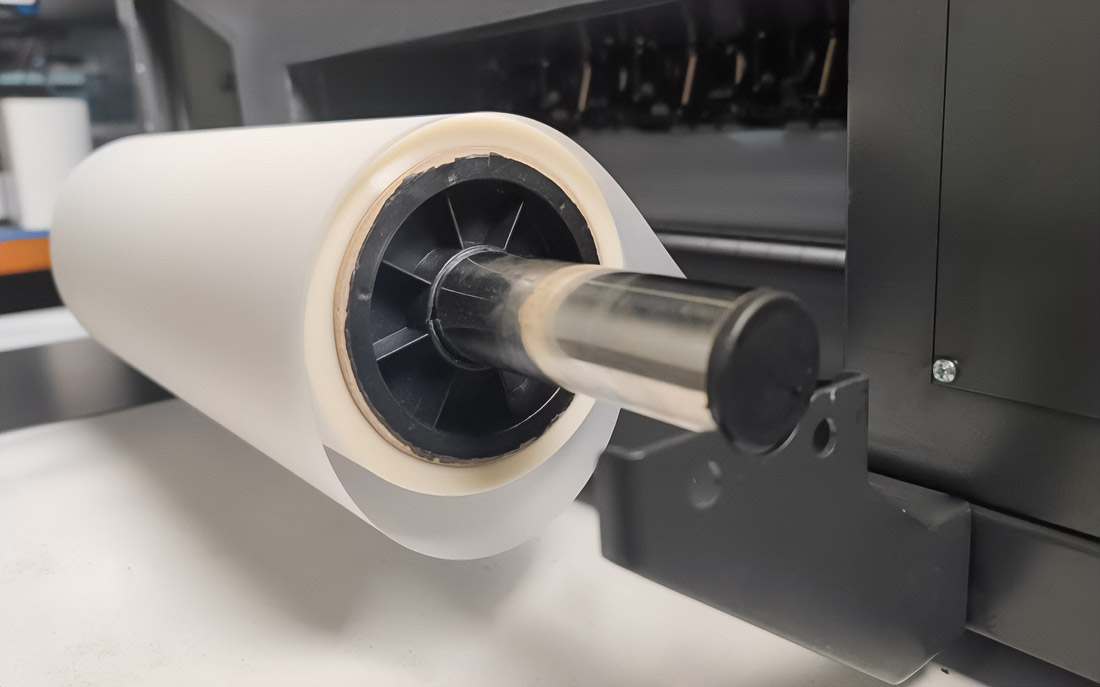

After processing in RIP software, the image is printed with pigment ink on PET film. While the layer remains wet, adhesive powder is applied. Its distribution should be uniform. An excess leads to a rough texture, a lack leads to poor adhesion and subsequent cracking.

The curing stage activates the powder. It should melt, but not overheat. This is where the future wash fastness and stretch resistance of the print are laid.

Materials, Fabrics, And Transfer Parameters

DTF printing works with cotton, polyester, blended and elastic fabrics without pretreatment. This expands the scope of application, but requires fine-tuning of the parameters. For synthetics, a lower temperature is more often used to avoid deformation and migration of the dye.

Thermal transfer is performed at a temperature of about 300–320 °F and a holding time of 15–20 seconds. The pressure should be stable. Too weak leads to detachment, too strong impairs the hand feel and can damage the tissue structure.

After the transfer, hot peel or cold peel is used, depending on the type of film. The final pressing — final press — fixes the image, improves adhesion and makes the surface more uniform.

Quality, Defects And Stability Of The Result

Quality control in DTF is impossible without regular maintenance. The nozzle check prevents banding and color skipping. Ghosting occurs when the film is displaced, most often due to unstable pressure or premature opening of the press.

The humidity of the air has a direct effect on the process. At low humidity, the ink dries faster, and the risk of clogging increases. At high temperatures, the adhesive powder may stick together, disrupting the uniformity of the layer. The optimal range is about 40–60% RH. If the process is set up correctly, DTF prints can withstand more than 50 washes without noticeable color loss. Stretch test confirms elasticity, and the final look maintains a balance between density and softness.